Assuring Excellence: The Ultimate Guide to Steel Bakeware Quality Control

Have you ever wondered how the baking trays or cake pans you use in your kitchen are checked for quality? What are the main aspects that influence the longevity and function of these crucial kitchen tools? As the leader of Bonray, a successful B2B metal bakeware manufacturer, I’d like to share some perspectives on the usual inspection criteria for steel bakeware quality control.

Material testing, dimensional checks, surface finish inspection, and performance testing are some of the usual inspection criteria for the steel bakeware quality control. These criteria help to guarantee that the baking trays or cake pans you use are safe, dependable, and capable of ensuring excellent bakeing results.

Why Strict Quality Control of Steel Bakeware Matters?

Quality control in the production of steel baking pans includes more than just preventing burnt cookie bottoms (though it is one of the factors). It is about the durability, functionality, and safety of your kitchen. A strict quality control process is essential for several reasons:

1. Consumer Safety

Ensuring that baking trays or cake pans are made from food-grade materials and free from hazardous substances is crucial for consumer safety. By adhering to strict quality control standards, manufacturers can guarantee that their products are safe for use with food.

2. Product Performance

A well-designed and manufactured baking tray or roaster pan will offer even heat distribution, be warp-resistant, and have a smooth, non-stick surface. These attributes are essential for consistent baking results and ease of use. A rigorous quality control process ensures that these performance criteria are met.

3. Durability and Longevity

High-quality baking trays are designed to withstand repeated use and last for years. By implementing strict quality control measures, manufacturers can deliver products that offer lasting value to their customers.

4. Brand Reputation

A company that consistently produces high-quality bakeware will build a strong brand reputation, attracting more clients and fostering long-term business relationships. A robust quality control process plays a vital role in maintaining and enhancing a brand’s image in the marketplace.

What are the Certifications and Regulations for Steel Bakeware Quality Control?

Industry standards are similar to the baking recipe for producing steel baking pans. They are essential when producting and inspecting a high-quality bakeware. But what exactly are these criteria, and why should we care?

Some of the steel bakeware industry standards include:

ASTM STANDARDS

The American Society for Testing and Materials, known as ASTM, are used by many manufacturers, end-users, and regulators as a guideline to ensure quality and safety. It covers various aspects such as material quality, safety, performance when it comes to the inspection of metal bakewares. For instance:

1. ASTM A240/A240M

This standard specification covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications. If the bakeware is made from these materials, this standard could be relevant.

2. ASTM B209

This standard specification covers aluminum and aluminum-alloy flat sheet, coiled sheet, and plate in particular alloys and tempers. If the bakeware is made from aluminum, this standard might be used.

3. ASTM D3359 – Standard Test Methods for Rating Adhesion by Tape Test

This standard could be used to evaluate the adhesion of the non-stick coating to the metal substrate of the baking sheet.

4. ASTM D3363 – Standard Test Method for Film Hardness by Pencil Test

This standard could be used to evaluate the hardness of the non-stick coating, which could give some indication of its resistance to scratching and wear.

5. ASTM D4060 – Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

This standard could be used to evaluate the abrasion resistance of the non-stick coating, which is important for its durability and longevity.

ISO (International Organization for Standardization)

ISO is one of the leading international standards organizations, and they have a wide range of standards that could potentially apply to metal bakewares.

1. ISO 9001 – Quality Management Systems

This standard is one of the most widely recognized ISO standards. It sets out the criteria for a quality management system and is based on a number of quality management principles including a strong customer focus, the involvement of top management, a process approach, and continual improvement.

A company applying ISO 9001 to their production processes demonstrates a commitment to product quality and customer satisfaction.

FDA (The U.S. Food and Drug Administration)

The U.S. Food and Drug Administration is responsible for protecting public health by ensuring the safety and proper labeling of food products and their associated tools and materials, which includes bakeware.

1. Food Contact Materials (FCM)

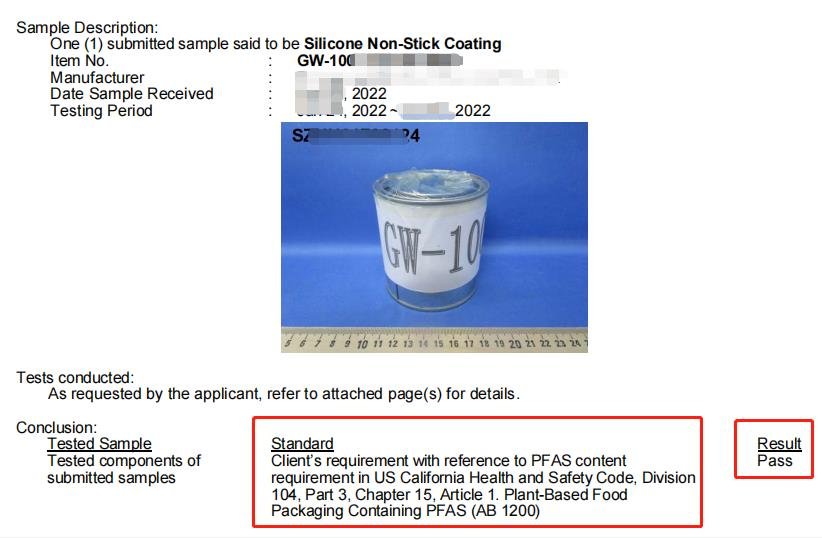

The FDA regulates materials intended to come in contact with food. Metal used in bakeware should be food grade and must not leach harmful substances into food during baking. For instance, substances like the non-stick coatings applied, must comply with FDA regulations for indirect food additives (Title 21 Code of Federal Regulations). According to FDA website, “It is the responsibility of the manufacturer of an FCS to ensure that food contact materials comply with the specifications and limitations in all applicable authorizations.”

Be sure the nonstick coating applied comply with the global regulations and the coating suppliers can provide the relevant certificates. On Teflon’s website, they listed the regulations their nonstick coating comply with and their perfomance with different temperature.

California Proposition 65

California Proposition 65, officially known as the Safe Drinking Water and Toxic Enforcement Act of 1986, requires the companies to issue clear and reasonable warnings about substantial exposures to chemicals that cause cancer, birth defects, or other reproductive damage.

Material composition:

CA Prop 65 includes more than 900 chemicals substances such as lead, cadmium, mercury and so on in their list. In this case, if the manufacturers do not want to include a warning label on their bakeware products, obtainning a CA Prop 65 valid test report to ensure the products do not contain listed chemicals is necessary and vital.

European Union Regulation

1. LFGB (Germany’s Food and Commodity Act)

This is the “Food and Commodity Act” in Germany. It sets limits on substances such as acetal resins and polyamides in Food Contact Materials (FCM). This includes overall migration, Polycyclic Aromatic Hydrocarbons (PAHs) content, and sensory analysis. It covers more aspects of food safety. Third-party lab testing is necessary for LFGB compliance.

2. EC Regulation No 1935/2004

Under this regulation, importers must ensure that their product is safe to use and compliant with FCM regulations in the EU. Stainless steel and other FCM in cookware should not affect the taste or smell of food or beverage. The regulation also sets limits on certain heavy metals and chemicals, such as lead, with an acceptable level between 1.5 to 4mg/L. Some EU member states may have additional requirements. For example, stainless steel cookware sold in France must contain at least 13% chromium.

3. EN 12983-2:2023

Published in February 2023, the latest versions of EN 12983-2: 2023 updates the performance requirements of non-stick coatings. It also requires third-party testing to verify compliance. Importers must assure compliance by careful supplier selection and verification of current test results.

Compliance with these certifications and industry regulations not only demonstrates a company’s commitment to quality and safety but also helps build trust and confidence among clients and end-users.

What Tests and Checks are Conducted Throughout the Inspection Process of Steel Bakeware?

1. Material Testing

The first stage in quality control is to ensure that the materials used in the manufacturing of baking trays or roasting pans meet the industry’s requirements. This includes ensuring that the materials are made of food-grade stainless steel or aluminum, and that they are free of toxic substances like lead and cadmium. Inspection of the raw materials should be always conducted before the mass production begins, ensuring the materials meet the required standards.

2. Dimensional Checks

Next, the baking trays undergo dimensional checks to ensure they meet the specified size and shape requirements. This involves measuring the length, width, height, and other critical dimensions of the trays using precision measuring tools like calipers and micrometers. Precision cutting and forming is an important production process because accurate dimension guarentee consistent baking results and can match with various ovens and baking accessories, inspection at this stage can help achieve consistent dimensions and shaping.

3. Surface Finish Evaluation

A baking tray’s surface treatment and coating application is essential for its non-stick performance and overall appearance. During this inspection process, the surface is assessed for smoothness, uniformity, and the presence of any defects like scratches, dents, or blemishes. The coating quality, is also examined to ensure its thickness and adhesion and free from defects like peeling or chipping.

4. Functional Performance Assessment

Finally, the steel bakeware products like baking trays, cake pans or roasting pans are subjected to various functional tests to evaluate their performance in real-world conditions. These tests may include heat distribution analysis, warp resistance testing, and load-bearing capacity evaluation. These assessments help ensure that the trays can withstand the rigors of daily use and deliver consistent baking results.

What are the measures that usually applied in the non-stick coating inspection of the metal bakeware?

Inspecting the non-stick coating of metal bakeware is critical to ensure its quality and safety. Here are several usually used measures:

1. Visual Inspection:

This is the most basic method to inspect a nonstick coating. Check the surface for obvious defects such as as bubbling, peeling, scratching, or discoloration. The coating should be smooth and free from of apparent flaws.

2. Thickness Measurement

The coating thickness can be measured with special tools such as an ultrasonic thickness gauge or a coating thickness gauge. These tools can assist in ensuring that the coating is thick enough to give ideal nonstick qualities yet not prone to chipping or cracking.

3. Adhesion Test

Cross-cut adhesion tests can be used to evaluate how well the coating adheres to the metal surface. This involves cutting a small grid pattern into the coating with a sharp blade, then using adhesive tape to pull off the grid section. If the coating remains intact, it indicates good adhesion.

4. Abrasion Resistance Test

A scrub tester can be used to simulate the effect of long-term usage on the non-stick coating. The tester rubs against the coating with a set force, and the degree of wear or removal of the coating can be observed and quantified.

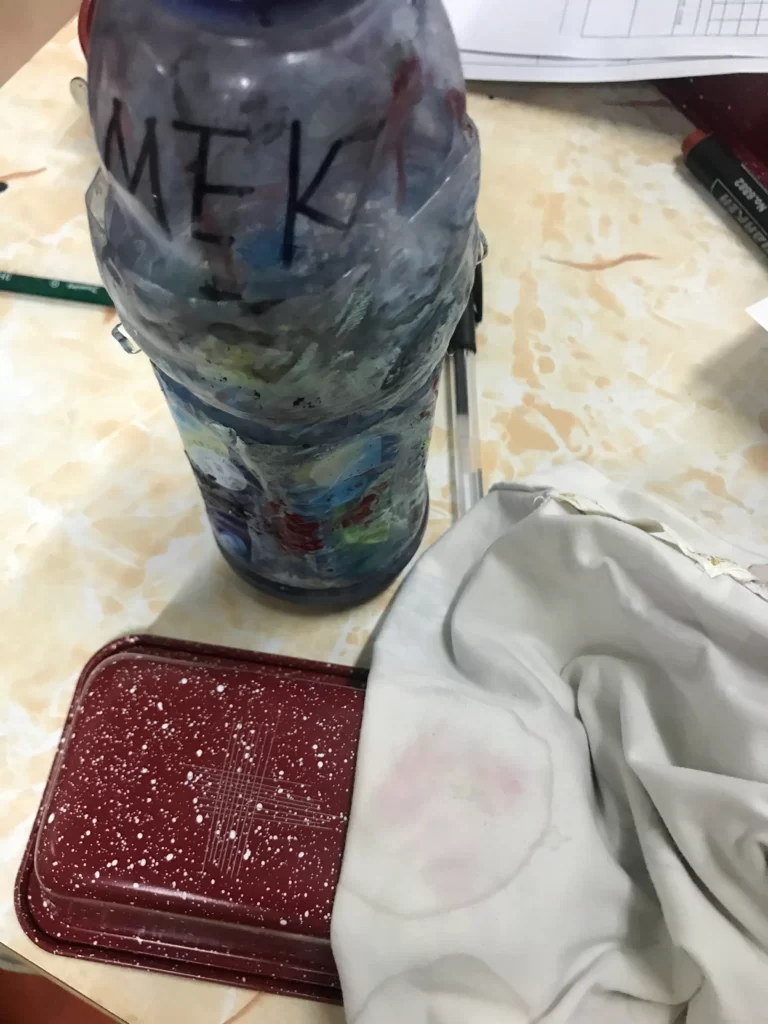

5. MEK Test

The Methyl Ethyl Ketone (MEK) Test is a solvent rub test often used to test the cure and adhesion of coatings, including non-stick coatings on metal bakeware. The MEK test is a quick method for testing the cure of a coating, but it’s a destructive test—meaning it damages the part of the coating where the test is performed. Therefore, it’s often performed on test samples rather than finished products. As MEK is a strong solvent that can dissolve or soften uncured or poorly cured coatings, it should be used with caution.

6. Heat Resistance Test

Non-stick bakeware is typically used in high-temperature environments. Therefore, it’s essential to test the coating’s ability to resist heat without breaking down, discoloring, or losing its non-stick properties.

7. Non-stick Performance Test

Non-stick performance test is a practical and simple way to evaluate the effectiveness of the non-stick coating on bakeware such as baking the batter without oil. A long-term non-stick performance test might involve repeating cooking and cleaning process to simulate typical usage and see how the non-stick coating holds up over time. A high-quality non-stick coating should maintain its non-stick properties even after many uses.

How are the inspection results documented and communicated to clients?

After the inspection process is completed, a comprehensive inspection report is prepared, documenting the results of each test and check. This report includes detailed information on any non-conformities, deviations, or defects identified during the inspection. The report is then shared with the client to help them make informed decisions about the quality and suitability of the baking trays for their specific needs.

FAQs about Steel Bakeware Quality Control

1. What are the important standards you value when performing quality inspection for steel bakeware?

There are various important aspects and criteria to consider while doing quality control on steel baking pans. Firstly, material composition should be checked to ensure that the steel is food-grade and without any harmful substances. Secondly, assess the thickness of the material can ensure the baking tray’s durability and heat distribution. Thirdly, check the dimension and the flatness of the baking trays to ensure they can fit properly in the baking equipment. Fourthly, check the surface coating and finishing ensure they are smooth without any bubbles, cracks or scratches. Fifthly, comfirm that the non-stick coatings applied on the baking trays comply with relevant food safety regulations.

2. What are the common defects you often find during the quality control process for steel bakeware product, and how do you fix them?

During the quality control process for steel baking trays or cake pans, several common defects may be identified. These defects can impact the trays’ performance, durability, and overall quality. Here are some common defects and the solution to fix them:

- Scratches: Minor scratches can be polished to restore the appearance, for deeper scratches, the damaged area should be repaired or the tray replaced if necessary.

- Dents or Deformations: Minor dents can often be corrected by carefully hammering. For severe deformations, the baking tray may need to be replaced to ensure the baking quality.

- Warping: Usually warping occur due to the improper use of the tooling or the defects of the tooling, we usully check the tooling and correct it after warping occur. Warping would have bad impact on the baking results that we would replace the baking trays with this defects.

- Coating damage: If the coating damage is minor, it is possible to recoat the baking trays or replace them to ensure the non-stick quality.

3. How frequently do you perform quality control checks on steel bakeware, and does this frequency change based on the volume of production?

In general, to guarantee constant product quality, quality control checks should be carried out regularly. Quality control checks are performed at regular intervals, such as daily, weekly, or biweekly. For large quantity order, production quality check should be applied more frequently to ensure the consistency of product quality. Moreover, quality control checks can be conducted on a batch basis when dealing with large orders.

4. Can you explain the role of third-party inspections in your quality control process for steel bakeware?

Third-party inspections are sometimes essential in the quality control procedure for steel baking trays, because they are not directly related to the manufacturing process, and they can provide an objective and unbiased evaluation of the steel baking trays or roasting pans. Through their professional inspection, They can help to verify the trays meet the specified quality standards and criteria. Third party inspections can help to develop confidence and reputation in the industry.

5. What steps do you take to maintain consistency in quality across different batches of steel bake pans during the quality control process?

During the quality control process, it requires careful attention and adherence to the specified processes to maintain consistency in quality across numerous batches of steel bake pans. The following are the main steps used to ensure consistency:

- Standardized Quality Criteria: These criteria should include dimensions, material composition, construction, surface coating, and other relevant parameters.

- Detailed Inspection Procedures: These procedures should cover all vital aspects, including dimensional accuracy, surface coating quality, durability, and standard compliance.

- Inspector Training: Make sure that inspectors understand the required quality standards and have the knowledge and skills necessary to perform consistent tests.

- Sampling and Statistical Techniques: This ensures that an assessment of quality is based on a consistent sample size that appropriately represents the entire manufacturing batch.

- Regular Audits and Monitoring: This can help to identify any deviations during manufacturing.

- Continuous Improvement: Use inspection input, customer feedback, and market data to enhance production procedures and product quality.

- Effective Communication: To make sure that consistent quality objectives are understood and applied across several batches, share thoughts, discoveries, and lessons learned in time.

Conclusion

In conclusion, quality control is an organized process that ensures the highest standards are met throughout the manufacturing of steel bakeware. The common inspection include a variety of checks, like material testing, dimensional checks, surface finish evaluation, and functional performance assessment. The final goal is to ensure that consumers receive a tray that meets their expectations.

By adhering to strict quality control measures and industry regulations, manufacturers like Bonray can produce trays that meet the highest standards of performance, durability, and safety and build a strong brand reputation. As consumers, understanding the key aspects of quality control enables us to make informed decisions when selecting bakewares.