Perfecting Your Cake Pan: The Role of MEK Rub Test in Carbon Steel Bakeware Production

Isn’t it annoying when your carefully mixed batter sticks to your cake pan, destroying the shape and texture of your cake? The problem may not be your cooking ability, but rather the quality of the cake pan. Have you ever thought about how your ordinary cake pan can affect your baking results? Specifically, how does the Methyl Ethyl Ketone (MEK) Rub Test factor into making carbon steel bakeware? Let’s delve into these questions today to help you get the right cake pan.

The MEK Rub Test, a crucial quality check, is very important in the process of bakeware manufacturing. We use this test at Bonray, along with cutting-edge production methods, ensure the quality of our carbon steel pans and non-stick baking sheets.

Is there a difference between various bakeware materials?

Absolutely! Carbon steel bakeware, for example, has a higher heat conductivity than other materials, such as aluminum. This leads to evenly baked goods, with the desirable moist center and golden exterior. Bonray, as a leading bakeware manufacturer, is keen on producing the best baking sheets and pans made from carbon steel.

Understanding of Carbon Steel Bakeware

Carbon steel, the key material in top-quality cake pans, has special features that make it stand out. It spreads heat evenly for consistent cooking, is strong for long-lasting use, and light for easy handling. That’s why carbon steel pans have become a favorite among experienced bakers and beginners alike.

Why Carbon Steel Pans are a Bakeware Essential

Known for their heat efficiency and strength, carbon steel pans are a staple in professional and home kitchens alike. Their ability to endure high temperatures makes them versatile for all kinds of baking techniques. They hold and spread heat incredibly well, giving baked goods that perfect golden finish, which is essential for baking success.

Delving Deeper: The Science of Bakeware Manufacturing

The Role of a Bakeware Manufacturer in Manufacturing Quality Products

Producing bakeware is a process that requires precision and science. It includes a series of carefully controlled steps that change raw materials into finished products that meet the high standards of bakers around the world. A skilled bakeware manufacturer is key to providing top-notch baking tools. They watch each step of the manufacturing process closely, sticking to strict quality checks and tests, such as the MEK Test, to make sure you get the best baking sheet.

Ensuring Consistency in Carbon Steel Pan Production

Producing carbon steel pans requires consistency to ensure all products meet the same high quality standards. How does a bakeware manufacturer maintain uniform quality in their products? The answer is they do this by applying strict tests and standards. Every detail of the carbon steel bakeware, from its thickness and non-stick coating to its heat resistance, is carefully tested for the best performance.

What exactly is the MEK Rub Test?

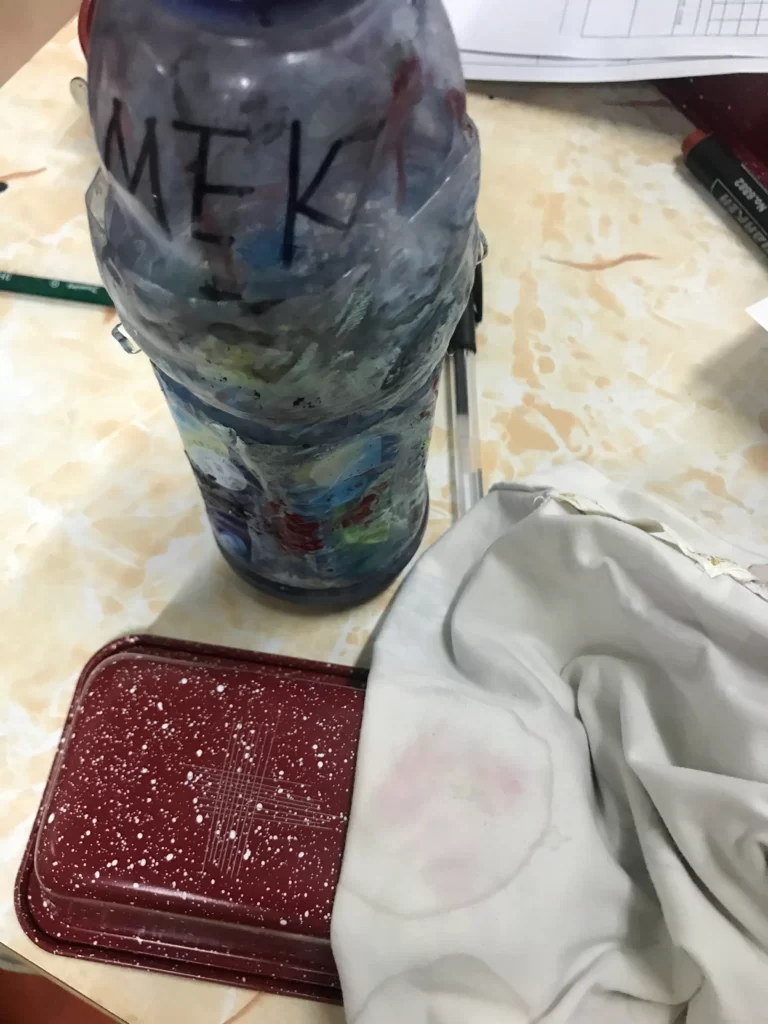

The MEK (Methyl Ethyl Ketone) Rub Test, a critical assessment tool, measures the durability and performance of a paint or coating on bakeware, specifically its resistance to solvents. This is vital for carbon steel bakeware as the coating plays a big role in the pan’s non-stick ability.

The test involves a cloth soaked in MEK being rubbed onto the bakeware surface for a certain number of times. If the coating remains untouched, it showcases high durability and resistance.

This stringent MEK Rub Test, performed by manufacturers, helps protect the non-stick feature of your baking sheet. Essentially, it’s a quality assurance method that ensures the longevity of the coating, which is integral for the bakeware’s non-stick properties.

General Outline of How the MEK Rub Test is Usually Conducted

- The MEK Test begins with the tester putting on the necessary Personal Protective Equipment (PPE) like gloves, goggles, and a lab coat to protect themselves from the strong solvent.

- Following this, the tester drenches a cloth or swab in MEK and proceeds to firmly rub the cloth back and forth over the coated surface. The number of “double rubs” (one forward and backward movement counts as one “double rub”) can range anywhere from 25 to 100, depending on the standards of the test.

- After completing the rubs, the tester examines the cloth and the surface. A fully cured and well-adhered coating will result in minimal to no coating material on the cloth, and the surface will show no signs of damage, such as softening or swelling.

- If the coating isn’t fully cured or poorly adhered, the solvent will cause it to dissolve or soften, leaving traces of coating material on the cloth and visible damage on the surface.

The MEK Test is an efficient way to test a coating’s curing process, but since it’s a destructive test, it’s usually performed on sample or test pieces rather than finished products. Safety measures should always be in place during this test due to the involvement of strong chemicals.

What are the Industry Standards and Acceptance Criteria?

The MEK Test follows the ASTM D5402 standard, an international standard developed by ASTM International.

This practice describes a solvent rub technique for assessing the solvent resistance of an organic coating that chemically changes during the curing process. This technique can be used in the laboratory, in the field, or in the fabricating shop. Test Method D4752 is the preferred method for ethyl silicate zinc-rich primers.

According to this standard, a high-quality coating should withstand a minimum of 50 double rubs without showing any signs of wear or degradation. If the coating starts to deteriorate before the 50th double rub, it does not meet the standard.

How MEK Test Influences Carbon Steel Bakeware

The MEK Rub Test, which measures the durability and quality of bakeware coatings, plays a pivotal role in ensuring your baking experience is smooth and worry-free. A baking pan that passes this rigorous test provides a reliable non-stick surface, ensuring evenly baked goods, hassle-free food release, and a breeze to clean up.

Making an Informed Choice: Your Guide to Quality Bakeware

Bakeware that has passed the MEK Test stands as a testament to performance and durability. Choosing such bakeware means enjoying a consistently smooth, non-stick baking experience, making your time in the kitchen more enjoyable and worry-free.

Knowing what distinguishes high-quality bakeware involves understanding the intricacies of its manufacturing process. It’s important to recognize the significant role of quality tests like the MEK Test and the remarkable value they add to the final product.

What is Bonray’s role in this?

At Bonray, we stand as a reputable bakeware manufacturer devoted to delivering top-tier baking sheets and cake pans. Our commitment to meticulous quality control processes, such as the MEK Test, showcases our dedication to you, our valued customer. We ensure that the bakeware you get is of supreme quality, primed to aid you in creating your culinary delights.

Conclusion

In baking, attention to detail is paramount. The bakeware you select and the quality assurance processes it’s been through, such as the MEK Test, can significantly impact your cake pan quality.

At Bonray, we deeply understand this and work relentlessly to provide top-notch carbon steel bakeware for a smooth and delightful baking experience. By choosing MEK tested products from a reputable bakeware manufacturer, you guarantee each carbon steel cake pan in your kitchen delivers top-tier performance, consistently. Isn’t it time you enhanced your baking journey?