كيفية إجراء اختبار سمك الطلاء غير اللاصق على أواني المخبوزات المعدنية باستخدام مقياس سمك الطلاء؟

هل تساءلت يومًا عن مدى متانة صينية الخبز المفضلة لديك المانعة للالتصاق؟ ما الذي يحمي خبزك من الالتصاق، وكم من الوقت ستدوم؟ هل من الضروري حقًا قياس سماكة الطلاء المانع للالتصاق، وإذا كان الأمر كذلك، كيف؟

إليك إجابة سريعة ومفيدة: يمكن قياس سُمك الطلاء غير اللاصق على أواني الخبز المعدنية بدقة باستخدام جهاز يسمى مقياس سماكة الطلاء. يُعرف في كثير من الأحيان باسم مقياس الطلاء، وهو أداة مفيدة لقياس سُمك الطلاء المانع للالتصاق على أواني الخبز المعدنية. إن فهم هذه الطريقة ضروري للحفاظ على جودة ومتانة أواني الخبز الخاصة بك.

ما أهمية اختبار سماكة الطلاء غير اللاصق؟

تعتبر مراقبة الجودة أمرًا حيويًا في إنتاج أواني الخبز المعدنية في حين أن سمك الطلاء المانع للالتصاق هو أحد العوامل المهمة. إذا كان الطلاء رقيقاً جداً، فلن يدوم طويلاً، أما إذا كان سميكاً جداً، فقد يتشقق أو يتقشر.

من خلال الحفاظ على السماكة المناسبة، يمكن تحسين أداء أواني الخبز بشكل كبير. يضمن الطلاء المانع للالتصاق عالي الجودة نتائج خبز متناسقة وسهولة التنظيف والاستخدام طويل الأمد. إن فهم عملية الاختبار أمر مهم إذا كنت منتجًا أو تاجر جملة يرغب في تقديم منتجات متميزة لمستهلكيه.

ما هو مقياس سماكة الطلاء وكيف يعمل؟

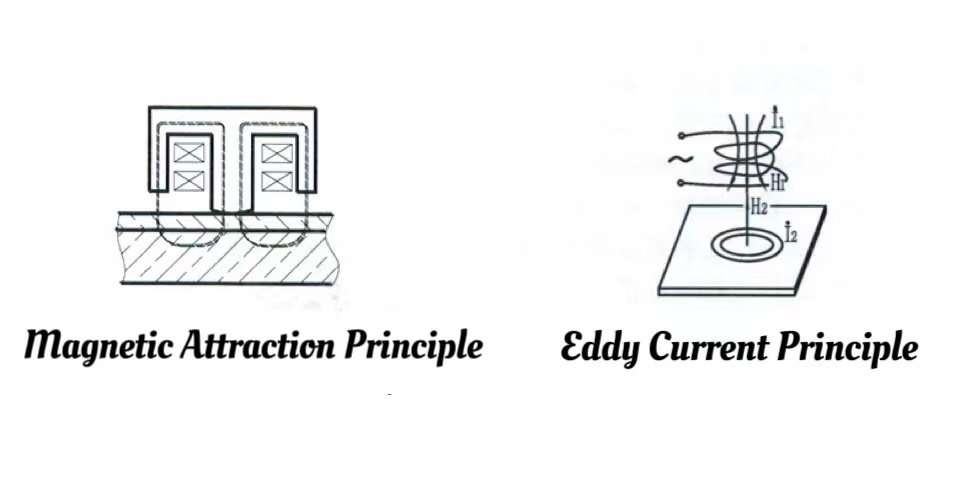

مقياس سُمك الطلاء هو جهاز يستخدم لقياس سُمك الطلاء على الركائز المعدنية. واعتماداً على نوع المقياس ومواد الطلاء، فإنه يعمل عبر مبادئ التيار المغناطيسي أو التيار الدوامي.

"قد تساورك الشكوك حول "كيف تقيس سماكة الطلاء غير اللاصق بدقة؟ بفضل تقنيتها المتقدمة، تستخدم هذه المقاييس مجسات مغناطيسية أو غير مغناطيسية لقياس سُمك الطلاء. عندما يوضع المسبار على السطح المطلي، فإنه يقيس المسافة إلى القاعدة المعدنية، أي سُمك الطلاء.

لمزيد من الفهم التفصيلي لكيفية عمل هذه المقاييس، يمكنك زيارة هذا رابط الموارد.

كيفية إجراء اختبار السماكة؟

نقوم عادةً بإجراء عملية اختبار السماكة باستخدام مقياس سماكة الطلاء في الخطوات الأساسية التالية:

1. معايرة المقياس

قبل الاختبار، يجب معايرة المقياس لضمان دقة القياسات. طرق المعايرة الشائعة الاستخدام لمقاييس سماكة الطلاء هي معايرة نقطة الصفر والمعايرة متعددة النقاط.

- المعايرة الصفرية: يتم إجراؤها على الركيزة المعدنية (غير المطلية) للتأكد من أن قراءة المقياس صفر. ضع المسبار على قطعة العمل غير المطلية واضغط على زر "صفر" لضبط المعايرة الصفرية.

- معايرة متعددة النقاط: يتم إجراؤها على معيار مطلي أو رقاقة/رقاقة ذات سمك معروف، مثل 25 ميكرومتر، 50 ميكرومتر، 125 ميكرومتر، 250 ميكرومتر، 500 ميكرومتر. ضع المسبار على المعيار المغلف، ثم قم بقياس كل رقاقة معدنية. قارن قراءة المقياس بقيمة سُمك الرقاقة. يجب أن تكون قراءة المقياس في حدود ± 2% من قيمة سُمك الرقاقة.

2. تحضير أواني الخَبز

نظف سطح أواني الخبز لإزالة أي أوساخ أو بقايا قد تؤثر على القراءة.

3. قياس سماكة الطلاء

ضع مسبار القياس على السطح المانع للالتصاق. سيقيس لك المقياس سُمك الطلاء.

4. كرر الاختبار

كرر هذه الخطوة في نقاط مختلفة على أواني الخَبز للحصول على متوسط قراءة السُمك.

5. تسجيل البيانات

بعد الانتهاء من أخذ جميع القراءات، قم بتسجيلها للرجوع إليها في المستقبل ومراقبة الجودة.

خاتمة

في الأساس، تحدد سماكة الطلاء المانع للالتصاق جودة أواني الخبز المعدنية وطول عمرها وأدائها العام. مقياس سماكة الطلاء هو أداة ضرورية لقياس السماكة والتأكد من أن أواني الخبز الخاصة بك مرضية. باستخدام هذه المعلومات، ستتمكن من الحفاظ على أعلى معايير الجودة في أواني الخبز المعدنية الخاصة بك. ففي النهاية، يضمن المنتج الموثوق به رضا العملاء وثقة العلامة التجارية والنجاح على المدى الطويل.