How to Conduct the Thickness Test for Non-Stick Coating on Metal Bakeware by Using a Thickness Coating Gauge?

Have you ever wondered about the durability of your favorite non-stick baking tray? What protects your bread from sticking, and how long will it last? Is it really necessary to measure the thickness of the nonstick coating, and if so, how?

Here’s a quick and helpful response: the thickness of non-stick coating on your metal bakeware can be accurately measured using a device called a thickness coating gauge. Often known as a paint meter, it is a handy tool for measuring the thickness of the nonstick coating on metal bakeware. Understanding this method is essential for keeping the quality and durability of your bakeware.

Why is Testing the Thickness of Non-Stick Coating Important?

Quality control is vital in the production of metal bakeware while the thickness of the nonstick coating is one of the important factors. If the coating is too thin, it won’t last long, but if it’s too thick, it may crack or peel off.

By maintaining the proper thickness, the performance of your bakeware can be greatly enhanced. A high-quality nonstick coating guarantees consistent baking results, easy cleanup, and long-lasting usage. Understanding the testing process is important if you’re a producer or wholesaler who wants to provide outstanding items to his consumers.

What is a Thickness Coating Gauge and How Does it Work?

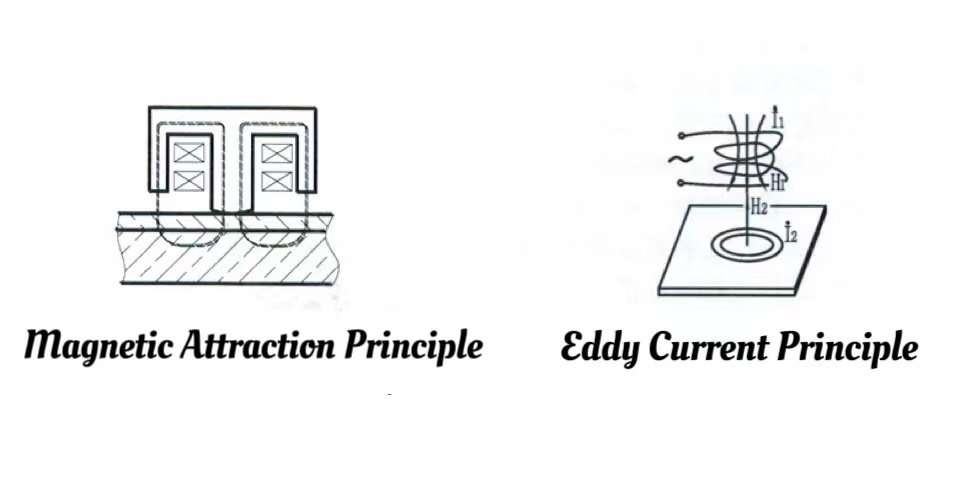

A thickness coating gauge is a device used to measure the thickness of coatings on metal substrates. Depending on the gauge type and coating material, it functions via magnetic or eddy current principles.

“How does it accurately measure the thickness of non-stick coatings?” you may in doubt. Thanks to its advanced technology, these gauges use magnetic or nonmagnetic probes to measure the thickness of the coating. When the probe is placed on the coated surface, it will measure the distance to the metal base, that is, the thickness of the coating.

For more detailed understanding of how these gauges work, you can visit this resource link.

How to Conduct a Thickness Test?

We usually conduct a thickness test process using a thickness coating gauge in the following basic steps:

1. Calibrate the gauge

Before the test, the gauge must be calibrated to guarantee precise measurements. The commonly used calibration methods for coating thickness gauges are zero-point calibration and multi-point calibration.

- Zero calibration: It is performed on the metal (uncoated) substrate to ensure the gauge reads zero. Place the probe on the uncoated workpiece and press the “zero” button to set the zero calibration.

- Multi-point calibration: It is performed on the coated standard or a foil/shim with a known thickness, like 25um, 50um, 125um, 250um, 500um. Place the probe on the coated standard, then measure each foil. Compare the gauge reading to the foil thickness value. The gauge reading should be within ±2% of the foil thickness value.

2. Prepare the bakeware

Clean the surface of the bakeware to remove any dirt or residues that might affect the reading.

3. Measure the coating thickness

Place the gauge probe on the nonstick surface. The gauge will measure the coating’s thickness for you.

4. Repeat the test

Repeat this step at different points on the bakeware to get an average thickness reading.

5. Record the data

After you’ve taken all of the readings, make a record of them for future reference and quality control.

Conclusion

In essence, the thickness of nonstick coating determins your metal bakeware’s quality, longevity, and overall performance. A thickness coating gauge is a must-have instrument for thickness measuring and ensuring that your bakeware is satisfying. With this information, you will be able to maintain the highest quality standards in your metal bakeware items. Afterall, a reliable product ensures customer satisfaction, brand trust, and long-term success.