Why Molding Matters: The Secret Behind Perfect Roaster Pans for Mass Production

Have you ever wondered how metal bakeware like roaster pans can be consistently manufactured with the same quality and design? Why is molding an essential step in mass production? What benefits can businesses reap by investing in molding before mass production begins?

The answer to these questions lies in the importance of molding in ensuring product quality, efficiency, and cost-effectiveness in the mass production of metal bakeware, such as roaster pans.

What is mold building or tooling building?

Mold building or tooling building for metal bakeware refers to the process of creating custom molds and tools that are used to manufacture the bakeware such as cake pans, roaster pans, bread pans, and other bakeware items.

The process of mold building or tooling building begins with the design of the mold or tool, which is typically done using computer-aided design (CAD) software. Once the design is finalized, a mold or tool is created using various techniques such as machining, injection molding, or casting.

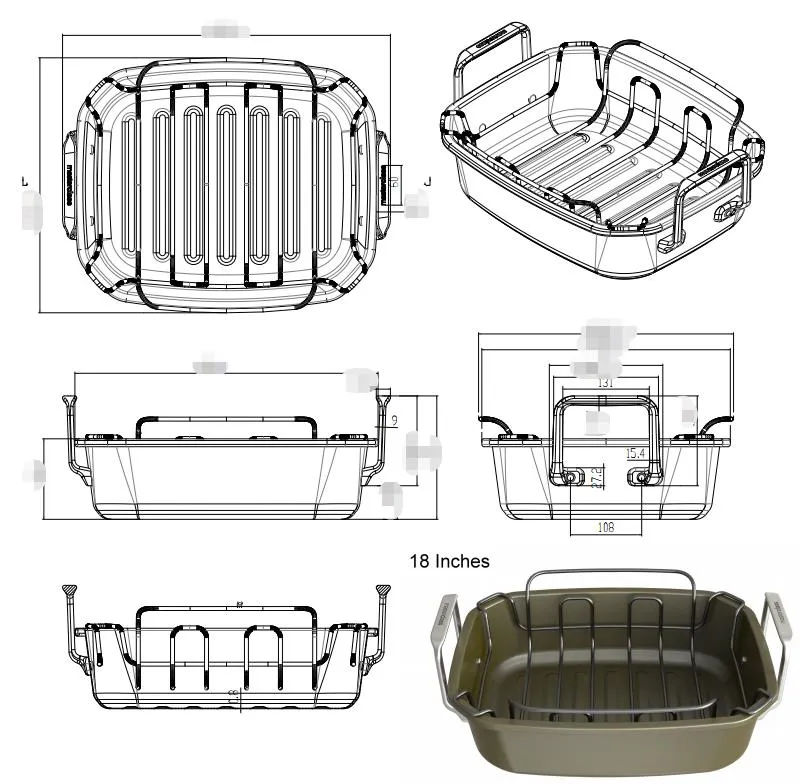

CAD design effect of the custom roaster pan

What is the purpose of molding in the production of roaster pans?

Molding is a crucial step in the manufacturing process that involves creating a mold, which is a hollow cavity that shapes molten metal into the desired form. This process helps achieve consistent quality, design, and functionality across all units produced. Building the mold before mass production commences ensures that the final products meet the required specifications and adhere to industry standards.

Mold for the roaster pans

Why is it important to invest in high-quality molds?

Investing in high-quality molds is essential to maintain product quality and reduce the risk of defects. A well-designed mold ensures precise dimensions and a smooth surface finish, which are crucial for metal bakeware like roaster pans. In addition, high-quality molds have a longer lifespan, allowing for more production runs before needing replacement.

How does molding contribute to production efficiency?

Efficiency is a significant factor in any manufacturing process. Molding contributes to efficiency by allowing for the rapid and consistent production of identical units. Once the mold is created, the manufacturing process can be streamlined, resulting in higher production rates and shorter lead times. This ultimately translates to better customer satisfaction and a competitive edge in the market.

How does molding impact cost-effectiveness?

Molding can lead to cost savings by reducing material waste and minimizing the need for additional finishing processes. The use of molds ensures that each unit produced is identical, which means that there is less variation in quality and fewer defective units. This uniformity reduces the amount of material that would otherwise be discarded during the production process. Moreover, well-designed molds can eliminate or reduce the need for further finishing processes, such as polishing or grinding, which can contribute to lower production costs.

What are the factors to consider when designing a mold for roaster pans?

When designing a mold for roaster pans, manufacturers need to consider several factors to ensure optimal results:

- Material selection: Choosing the appropriate material for the mold is crucial, as it directly affects the mold’s lifespan and performance. Some common materials used in molding include steel, aluminum, and beryllium-copper alloys1.

- Design complexity: The complexity of the roaster pan’s design will impact the mold’s design and manufacturing process. More intricate designs may require additional steps or specialized equipment.

- Mold maintenance: Regular maintenance of the mold is vital to ensure its longevity and consistent performance. This includes cleaning, lubricating, and inspecting the mold for signs of wear or damage.

Conclusion

In conclusion, building molding before mass production of roaster pans is essential for ensuring consistent product quality, improved efficiency, and cost-effectiveness. Investing in high-quality molds and considering crucial factors in mold design can significantly contribute to the success of a business in the metal bakeware industry.

As a leading metal bakeware manufacturer, Bonray boasts strong research and development capabilities, providing top-quality products that meet the diverse needs of our clients. Choose Bonray for your next brilliant metal bake pans project and experience the benefits of our expertise and commitment to excellence. Contact us today to discuss your requirements and let our professional team help you achieve success in your business.